Innovation

December 2025: Innovation Index, Women Entrepreneurs & MIF in Action

A snapshot of how December unfolded at MIF—through ideas, partnerships, and on-ground engagement.

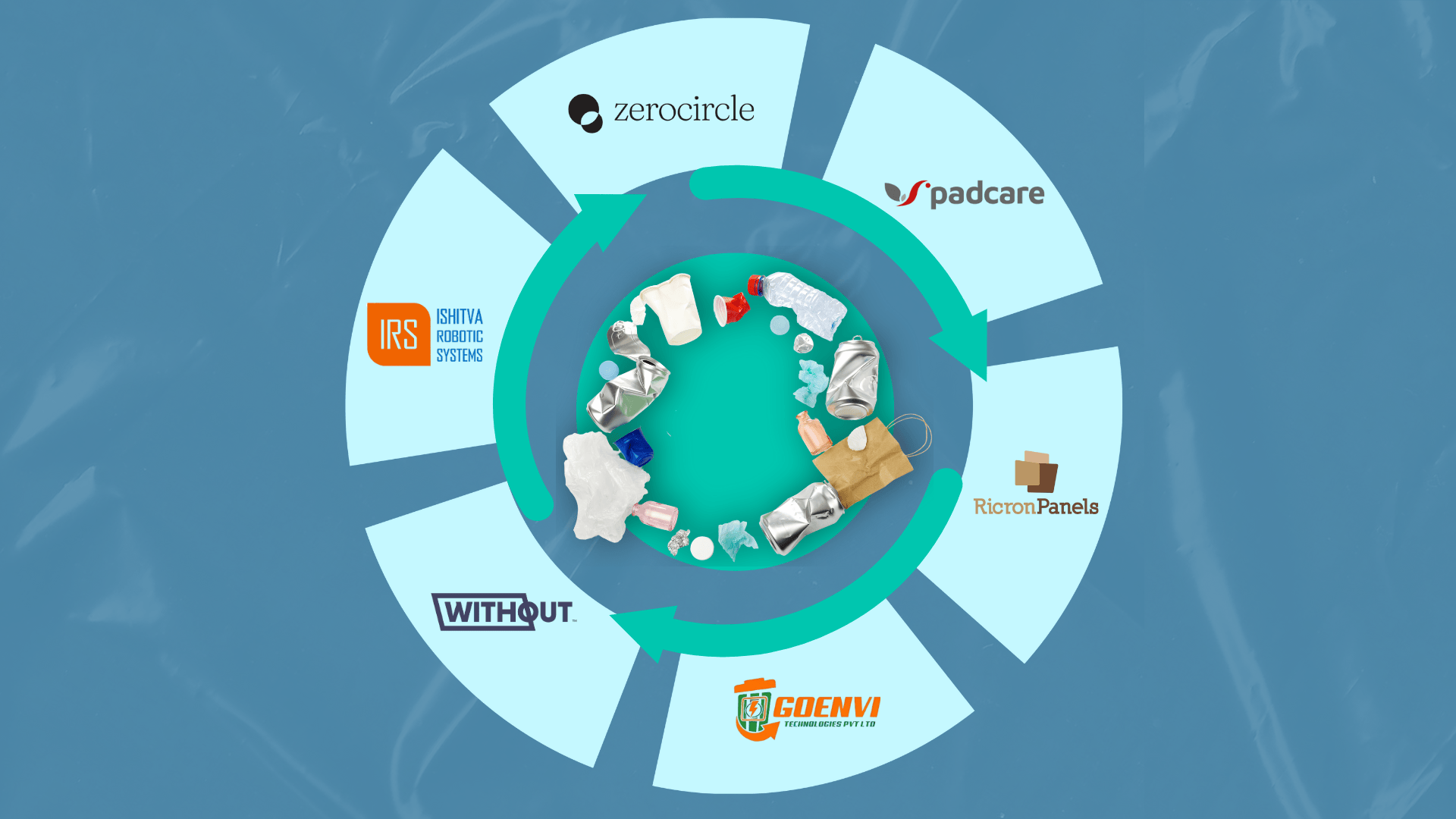

Backed by MIF’s Scale-Up, six startups are building a smarter plastic economy—local, innovative and built to last.

What we call plastic waste is often a missed opportunity. By reimagining its journey—from creation to reuse—innovators are building smarter, more sustainable alternatives. Scale-Up, Marico Innovation Foundation’s no-equity accelerator, is supporting six such path-breaking startups working across the plastic value chain.

Beyond collection, plastic waste needs to be dealt with, close to where it’s generated. Goenvi Technologies builds decentralised waste-to-fuel units using catalytic thermal decomposition. Their systems slash the cost and complexity of setting up pyrolysis plants, turning mixed plastic waste into usable fuel at scale. No middlemen, no miles of transport—just local action with global impact.

One of the biggest inefficiencies in recycling is human error in sorting. Ishitva Robotic Systems is fixing that with AI-powered machines like Netra and Suka. These systems use computer vision to identify plastic types, brands, and colours with high accuracy, processing up to six tonnes of waste per hour. Sorting is no longer the bottleneck; it’s a competitive advantage.

Sanitary pads are one of the most stubborn waste streams—chemically complex and taboo to handle. PadCare has engineered a patented process that sanitises and separates used pads into cellulose and plastic, both of which are recyclable. Their innovation is equal parts waste management and dignity infrastructure. The recovered cellulose and plastic are repurposed into end-use materials such as paper, packaging and stationery.

Ricron takes multi-layered plastic packaging waste, which is difficult to process and often dumped, and transforms it into robust construction materials. Their panels can replace MDF and plywood in schools, hospitals, and homes. They are essentially offering a moisture-proof, termite-resistant solution without cutting down any trees.

The cleanest solution to plastic pollution is to never create plastic at all. Zerocircle makes packaging from seaweed: gully biodegradable, dissolvable, and safe for marine life. They’re not recycling plastic. They’re out-designing it.

Multi-layered plastics are often labeled “unrecyclable.” Without disagrees. They use advanced chemical processes to convert this trash into high-quality consumer products, like sunglasses. Beyond the material, they’ve built a model that includes waste pickers as economic partners, proving that circularity can also be just.

Each of these six startups addresses a specific failure in the plastic value chain, and together, they form a closed loop that’s functional, scalable, and grounded in science. It’s not theory. It’s already happening. And it’s built to last.

Through MIF’s Scale-Up accelerator, they’ve had the support to take ideas further, and to refine their models, grow responsibly, and stay focused on impact. That’s what Scale-Up is built for: helping groundbreaking solutions to India’s most pressing challenges become practical ones, at scale.

A snapshot of how December unfolded at MIF—through ideas, partnerships, and on-ground engagement.

Learn how Rocket Learning is building a national movement for joyful early education, using WhatsApp, YouTube, and smart design, to reach 4 million children.

India's startup ecosystem has evolved into a global innovation hub, driving economic growth, job creation, and technological advancement across diverse sectors.

Get insights from entrepreneurs, investors, and change-makers on innovation,

success and what it takes to get there.