About Canvaloop

Traditionally, sustainability and fashion have stood on opposite ends—but Canvaloop is challenging that divide.

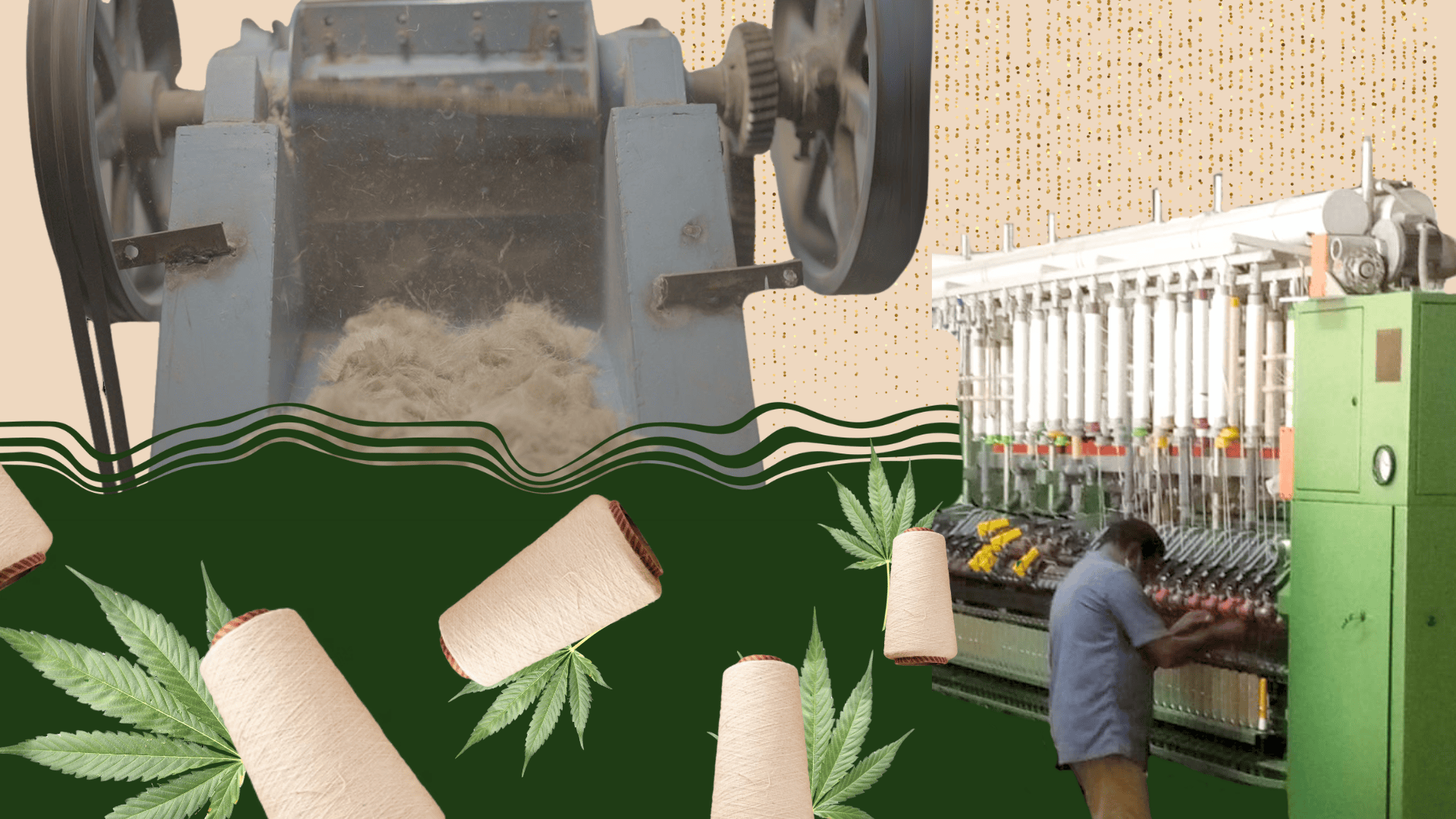

This material sciences startup is transforming agricultural waste of hemp, flax, banana, pineapple, nettle, and oilseed crops into high-performance, 100% biodegradable textile fibers. Using a proprietary chemo-mechanical three-step process, Canvaloop extracts cellulose from crop waste, which is then processed through a patented system into breathable, durable, anti-microbial, and anti-UV yarns. These materials match the physical properties of cotton but are significantly more sustainable.

Canvaloop’s technology offers a solution to two major environmental challenges. First, it converts crop stubble into sustainable fiber, preventing stubble burning and reducing air and land pollution. Second, its closed-loop process uses just 0.1% of the water conventional textile methods require, with zero liquid discharge and only non-hazardous chemicals.

The impact extends beyond the environment. By sourcing raw material from Indian farms, Canvaloop offers new income opportunities to farmers and creates rural employment by partnering with informal waste workers and marginalised communities.

Today, Canvaloop collaborates with leading apparel brands to produce sustainable T-shirts, shirts, denim, and carpets. It’s a regenerative alternative the industry can adopt at scale—one that combines circularity with rural empowerment.

Canvaloop at MIF’s Scale-Up

Canvaloop was inducted into the Scale-Up program in October 2024 for its pioneering work in agricultural waste management and sustainable fibre innovation. Through Scale-Up, MIF is currently supporting Canvaloop in setting up a decortication unit in India to enable local procurement of raw materials and reduce import dependency.

As of 2025, Canvaloop continues to be an active Scale-Up participant. MIF is confident in its potential to grow into a large-scale enterprise driving transformative environmental impact across the textile and agriculture sectors.